highest quality

many years of experience

practical solutions

wide range of packaging

Technology

Corrugated cardboard

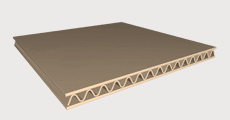

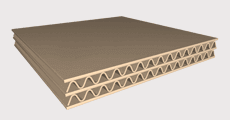

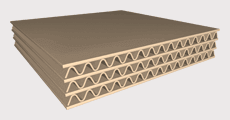

Corrugated cardboard is made of a few layers of paper. The external layers are straight and the internal are corrugated or fluted. The structure of cardboard acc. to type is presented below:

a. three-layer cardboard

b. five-layer cardboard

c. seven-layer cardboard

The following types of flutes can be distinguished:

E flute (micro flute) with height from 1.1 mm to 1.7 mm

B flute with height from 2.5 mm to 3.0 mm

C flute with height from 3.0 mm to 3.7 mm

or, in case of 5-layer and 7-layer cardboard, flute combinations, e.g. BC, EB, EE, BB

Corrugated cardboard and packaging is most often measured with such gauges as:

FCT - flat crush resistance - measured in N - it is the force that must be applied on the sheet so that the flute is crushed. A cardboard sheet lied horizontally in the press

ECT - (vertical) column crush resistance - measured in N - it is the force that must be applied on the sheet so that it is crushed. A cardboard sheet lied vertically in the press

BCT

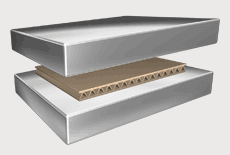

BCT - box compression resistance - measured in N - this test consists in compressing the box between two parallel plates until the side walls of the box crush

Different types of paper are used to produce corrugated cardboard which impact the cardboard quality and strength.

Basic types of paper are:

recycled paper;

testliner;

kraftliner;

The other important factor having impact on the cardboard quality is density of applied paper. Density and type of paper used for manufacture of corrugated cardboard designate its quality and strength.

The most common cardboard external layer is:

Grey / grey

White / grey

White / white

Specification of strength of corrugated cardboard box

Our Clients often deal with the problem of selection of cardboard for packaging so that the cardboard box meets the strength requirements and, at the same time, is cheap.

We, as a packaging manufacturer, knowing the basic parameters, such as: box circumference, cardboard thickness, cardboard ECT, can calculate the BCT parameter, i.e. box strength.

A cardboard box selected in this manner will meet the Client's requirements as to content protection and, at the same time, will optimise the costs of its purchase.

BCT=5.87*square root (circumfer.*thick.)*ECT:

where:

BCT - box strength [kg]

circumfer. - box circumference (2*length + 2*width) [m]

thick. - corrugated cardboard thickness [mm]

ECT - cardboard strength [kN/m]

The calculated packaging strength is the limit strength. It is necessary to remember that the result of calculation is approximated. The actual packaging strength is subject to many more factors, such as: air humidity, moisture of packed product, distance from the target recipient, stacking pallets, storage time and many others. For this reason, it has been assumed that the obtained result is multiplied by a safety factor of 0.60. Then, we can be certain that the selected box is sufficient.

We also offer you any types of packaging additions, such as:

cardboard corners,

cardboard partitions,

cardboard trusses.

Ecology

Both corrugated and non-corrugated cardboard is an eco-friendly material. Used packaging can be recycled. The majority of our packaging is made with particular consideration of eco-friendly processes. The cardboard boxes have a disposable nature and are fully recyclable. Our company can collect recycling waste after it is baled at the client's.